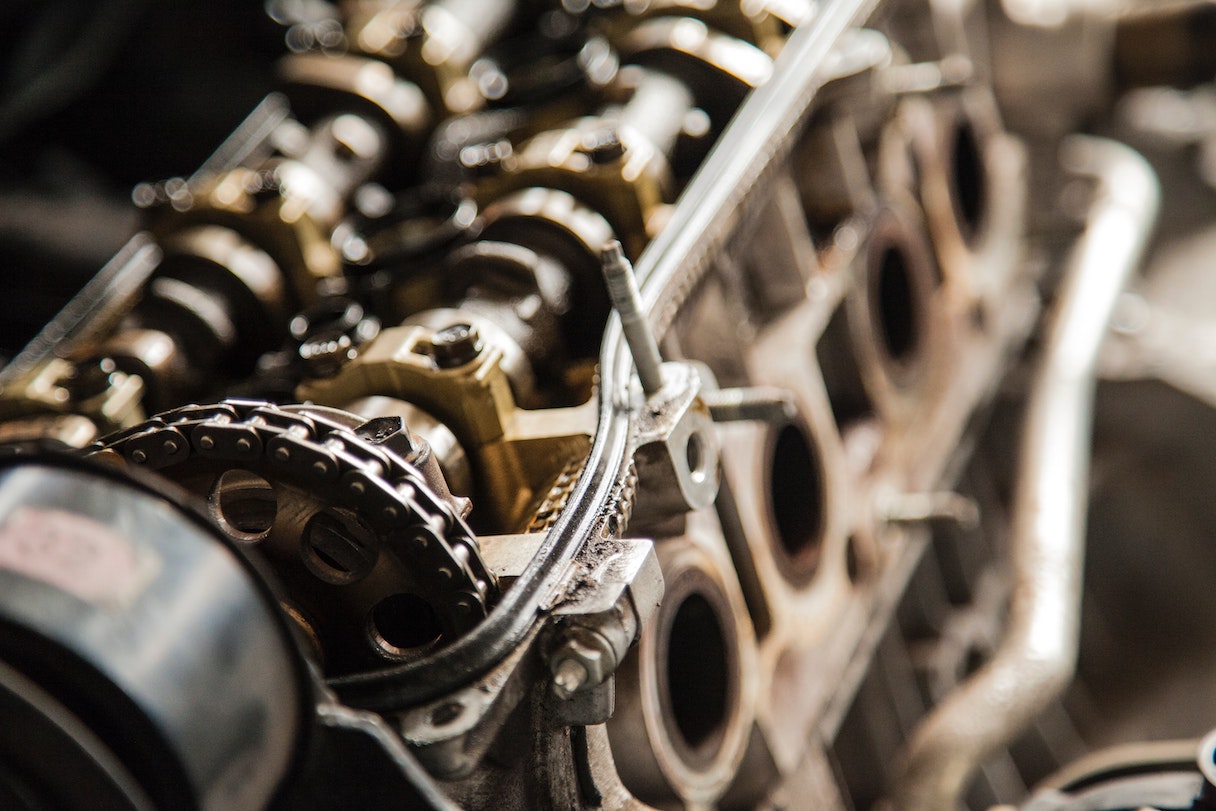

Predictive Quality Solution for Die Casting in Car Manufacturing

Data-driven recommendations on how to tune equipment settings

Traditional quality management is costly and ineffective

As part of the effort to reduce the scrap rate, the supplier wanted to understand how the settings on their casting machines were affecting the eventual quality. Their current quality initiatives were based on manually-designed experiments that were time consuming and interrupted regular production.

In collaboration with a leading technology consulting company, we developed a data-driven predictive quality management solution to identify the relationships between machine settings and quality, with the goal of determining optimal equipment settings that would reduce the scrap rate.

Uncovering meaningful relationship between machine settings and quality

-

Evaluating multiple settings simultaneously

Compared to the manually-designed experiments where only one or two settings could be changed at a time, the model was able to mine historical data and evaluate the effects on quality considering dozens of settings at once.

-

Useful insights to adjust machine settings

The resulting tree shows insights such as the interaction between key variables, which helps to guide engineers as they tune the equipment settings.

Example tree for differentiating quality (variable names have been anonymized)

Reduced cost of poor quality

The insights from the trees empowered the engineers to refine the equipment settings, leading to lower scrap rates overall. The trees also identified areas of strength and weakness for each machine, enabling an optimization-based allocation of jobs to the machines to further increase quality.

Unique Advantage

Why is the Interpretable AI solution unique?

-

Verified with expertise

The engineers are comfortable making changes because they can see and verify the relationship with their expertise

-

Discovery

The model allows for the discovery of machine settings that affect quality which were previously unknown

-

Machine-specific recommendations

The trees highlight areas of strength and weakness for each machine, enabling better job allocation